Mask breathing resistance test: cyclic vs constant airflow

Regulated methods for testing the breathing resistance of facemasks usually involve the use of constant (static) flow. However, in real-world conditions, inhaled and exhaled flow is continuous and cyclic, which places different stresses on the filter media and affects the comfort of wearing the RPE. Therefore, for a more accurate understanding of the performance of protective filtering RPE, it is important to test the breathing resistance not only on a constant flow, but also on a cyclic (pulsating or sinusoidal) flow that reflects the actual breathing conditions of the RPE user, including breathing rate and depth, i.e., lung ventilation.

Benefits of dynamic breathing resistance testing in the design and manufacture of protective face masks:

- Increased comfort level

Dynamic testing accurately estimates the resistance during natural human breathing, helping designers to create RPE that provides the user with minimal breathing stress and maximum comfort.

- Optimisation of filtration

Results obtained under near real-world conditions allow designers to select the density and structure of filter media to balance respiratory protection and wearing comfort.

- Evaluation of filter media durability

By repeatedly cycling the material, it is possible to establish how long it retains its protective properties and resistance to increased drag.

- Additional validation of product quality

Extended product quality studies help to attract professional users who need maximum protection and confidence in the safety of RPE.

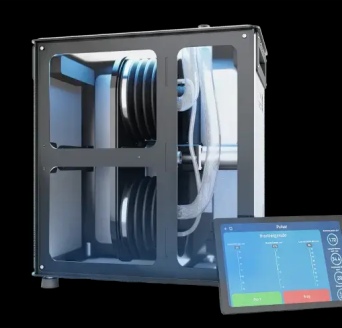

Test equipment for dynamic breathing resistance testing of protective face masks

Pulsar breathing machine from Second Breath range of testing equipment is designed to create a cyclic (pulsating, dynamic) air flow that accurately replicates human lung ventilation cycles and measures breathing resistance.

.png)

Main characteristics of ‘artificial lung’ type equipment PULSAR

- Equipped with bellows pumps to create a pulsating air flow.

- Simulates lung ventilation at user-defined parameters of respiratory rate and depth. Lung ventilation setting range: 5-120 dm³/min.

- Instantly enters the operating mode.

- Automatically calculates breathing resistance. Measuring range: -3.5 - 3.5 kPa.

- Controlled via Android app on a tablet PC or smartphone , commands are transmitted via Bluetooth.

- Breathing rate and depth parameters can be changed at any point in the test without stopping or restarting the equipment.

- Can be connected to a human torso or head mannequin, climatic chamber or other user systems (e.g., production line or other test equipment)

- Can be placed on a table or wheeled trolley. Weight is 25 kg or less.

The use of PULSAR test equipment in testing respirator facepieces and other filtering RPE allows developers to identify key aspects of filter media performance under conditions as close to real-world conditions as possible. PULSAR helps to simulate different scenarios of respiratory workload of the wearer of the RPE and determine for which types of work the RPE would be most suitable.

Dynamic testing helps to create RPEs with an optimal combination of comfort and efficiency, making them in demand in industry, construction, mining, civil protection, food and chemical industries - areas characterized by high demands on safety and comfort, as well as intensive loads and prolonged use.