Testing re-breathers, diving apparatus using a breathing simulator

Testing of closed-circuit and semi-closed-circuit re-breathers (CCR, SCR) and open-circuit SCUBA during development, production and conformity assessment is performed in accordance with EN 14143 and other applicable standards.

In practice, a key instrument for such evaluations is a breathing simulator test equipment, which reproduces controlled respiratory parameters and allows assessment of diving apparatus performance under high test conditions.

This article describes practical aspects of test equipment evaluation and the capabilities of the Pressure breathing simulator OXY ROBOT developed by SECOND BREATH OÜ.

Breathing performance testing of re-breathing diving apparatus

Regardless of breathing circuit type, test procedures focus on:

- apparatus performance at specified minute volume and respiratory frequency;

- stability of breathing gas composition and inhalation/exhalation conditions;

- checking operational duration of diving apparatus.

Such tests require instrumentation capable of reproducing work of breath (WOB) and controlled breathing parameters in accordance with defined test profiles.

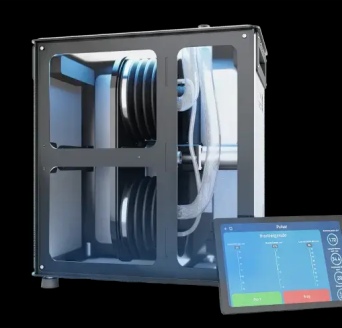

Capabilities of the pressure breathing simulator OXY ROBOT

OXY ROBOT Pressure is an automated breathing simulator designed for functional testing of re-breather apparatus (CCR, SCR) and diving apparatus (SCUBA).

Fig.1 Pressure breathing simulator OXY ROBOT

It allows simulating various scenarios of divers breathing in the apparatus under different loads to check the protective action time of RPE in accordance with design documentation, EN requirements, etc.

Key technical specifications

- Lung ventilation: 5 to 120 L/min

- Breathing rate: 10 to 41 min⁻¹

- Breathing depth: 0.5 to 3.1 L

- Breathing resistance: –6 to +6 kPa

- Exhaled gas temperature: 37 °C ± 1 °C

- Exhaled gas humidity: 96% ± 4% RH

- Exhaled CO₂ concentration: 4% vol.

- Operating high pressure: up to 600 kPa (6 bar).

These ranges cover standard test regimes specified for diving breathing apparatus and represent the base configuration of the system. Additional configurations can be evaluated upon customer technical requirements.

Laboratory integration and operation

Pressure breathing simulator OXY ROBOT is a compact, single-unit design that does not require permanent installation or special laboratory infrastructure.

The unit can be mounted on a trolley for manual relocation within the laboratory. Its design allows integration with a pressure chamber (not included in the scope of supply).

Fig. 2 Connection of the pressure chamber, test equipment, and diving apparatus

Depending on customer requirements, the test equipment can be supplied with a head manikin, including an optional heated configuration.

Automation of test equipment operations

OXY ROBOT Pressure does not require manual adjustment for test start-up, calibration, breathing mode configuration, stabilization or monitoring of breathing gas parameters.

The integrated hardware and software platform operates in fully automated mode, reducing parameter drift and minimizing operator influence on test results.

How works OXY ROBOT Pressure

Fig 3. Oxy Robot Pressure management

- The operator sets the required breathing parameters via the PC application, including breathing rate, breathing depth, lung ventilation, exhaled gas temperature and humidity, and breathing gas mixture parameters.

- The operator creates test modes, i.e. defines the minute ventilation values and time intervals during which the simulator reproduces the diver’s breathing.

- After the test scenario is created, the simulator is switched to the operating mode via the touchscreen interface (typically within 40 minutes). At this stage, no additional actions from the operator are required.

- During the test, the operator does not need to manually record test values; all parameters are automatically logged and compiled into a report with export capability. In addition to tabular data, the software generates a work of breath (WOB).

- If another apparatus needs to be tested using the same test scenario, the operator can simply select it in the application without reconfiguring the settings. This reduces preparation time and increases laboratory productivity.

- Based on the test results, the operator evaluates whether the tested sample meets the values specified in the design documentation and applicable standards.

Software functions

The system is supplied with dedicated PC software providing:

Before testing

- database of rebreathers, manufacturers, standards and operator profiles;

- configuration of breathing parameters and test load;

- selection of predefined test scenarios.

During testing

- real-time parameter visualization;

- automatic respiratory waveform generation;

- continuous data acquisition and logging.

After testing

- automated test report and test log generation;

- data export via USB.

Compared to mechanical or semi-automatic systems, OXY ROBOT Pressure significantly reduces operator workload.

The test equipment can be operated by personnel with basic training, allowing highly qualified specialists to focus on data analysis and R&D activities.

Application areas

The OXY ROBOT Pressure breathing simulator is intended for:

- R&D laboratories of diving equipment manufacturers;

- serial production quality control;

- certification testing.

Compact design, mobility and software-driven automation make it suitable for integration into existing laboratory environments.

Fig.4 Pressure breathing simulator OXY ROBOT

Conclusion

Breathing performance evaluation using test equipment is a mandatory stage in ensuring safety and conformity of diving breathing apparatus and re-breathers.

In-house test equipment reduce certification risks, shorten development cycles and ensure consistent product quality.

To receive a technical proposal for the breathing simulator OXY ROBOT Pressure, please contact:

📧 info@second-breath.ee

We will analyze your technical requirements and propose an optimal configuration for laboratory and conformity assessment testing.

_342x328_4c7.jpg)